Development and design department

To trim, saw, cut: When ideas start to take shape

Whether it concerns further development of our core products or a completely new development: Our design team consisting of 15 engineers and CAD technicians is characterized by high innovative strength. Thanks to our developments, we hold a multitude of patents. New products are created independently as well as in close co-operation with customers and partners.

Our development division is further enhanced by collaborations with external designers, research institutes and universities from the region.

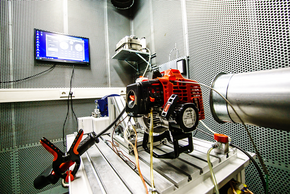

Test Center

Our team of experienced employees puts individual components, assemblies or complete devices through their paces.

12 air-conditioned test cabins allow reproducible tests close to the standards. Various measuring equipment ensures precise measurements of a wide range of parameters. In-house developments and customer devices are tested to an extended range throughout the entire development process. Prove the load capacity in customer-specific test setups and validate your products with Mogatec.

As a direct partner for OEM customers, we act as a service provider in the field of battery- and electric powered tools, from cordless screwdrivers to two-hand chainsaws. For the realization of new test projects, we are ready to design and develop customer-specific test setups.

Blade production

Place your trust in our decade-long experience with the manufacturing of cutting systems

In the course of our blade production for hedge trimmers and grass shears, we work with the latest laser technology. With more than 400 different blade versions and an annual production quantity of up to 750.000 blades, we are Germany-wide the leading manufacturer in this category.

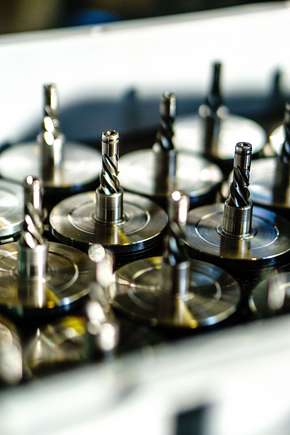

Production of milled and turned parts

Modern garden technology begins with accuracy

The second focal point of our component production are milled and turned parts, whether as separate components, assemblies or installed in completely assembled garden tools. The products include gearboxes, spur gears, eccentric and gearbox shafts as well as coupling components. They are made exclusively from high-grade steel and manufactured on modern CNC machines.

Cable manufacturing

Whether sample series, individual cables or large orders – We have the right connection

In our cable manufacturing we use automated wire cutting and stripping machines. In addition to classic cable lengths, we also manufacture specifically according to our customers’ individual wishes and ideas. Mainly stranded wires in the cross-section range of 0.12 to 2.5 mm2 are completed with crimp contacts, such as end sleeves, plug-in sleeves, flat plugs or various cable shoes. Each prefabricated cable has its own individual requirements, depending on the task.

Assembly / Quality assurance / Warehousing & logistics

We strive for optimized processes from assembly to delivery

Our assembly lines are only equipped with components from our own manufacturing facilities and from selected suppliers. Each product leaves the plant only after a quality-assuring final inspection. All processes are certified according to the ISO 9001 standard.

In order to allow short-term customer orders to be met in a fast and sufficient way, we rely on a flexible production as well as optimized logistics and warehousing on 20.000 m² storage area. Longstanding logistic partners enable us to guarantee on-time delivery.